How to Choose the Best Shipping Container Insulation for Your Needs

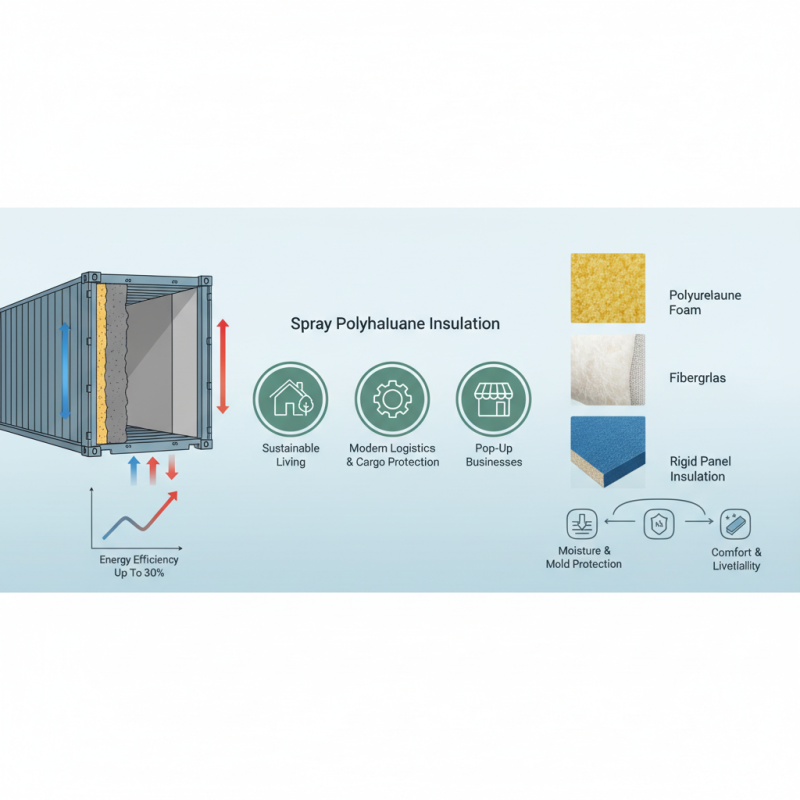

When it comes to optimizing the use of shipping containers for various applications, one of the most critical considerations is the selection of appropriate shipping container insulation. According to a report by the International Organization for Migration, insulated shipping containers can improve energy efficiency by up to 30%, making them vital for temperature-sensitive cargo and sustainable living spaces. Experts in the field, such as Dr. Robert Finch, a renowned insulation specialist, emphasize the importance of proper insulation: "Choosing the right shipping container insulation not only preserves the integrity of the goods transported but also creates a more sustainable solution for modern logistics."

The growing trend of repurposing shipping containers for homes, offices, and pop-up businesses underscores the need for effective insulation solutions. The North American Insulation Manufacturers Association reports that, as climate challenges increase, the demand for high-performing insulation materials in shipping container applications has surged. Proper shipping container insulation not only keeps interiors comfortable but also protects against moisture, mold, and extreme temperatures, making it essential for achieving both livability and functionality.

In this ever-evolving industry, understanding the various insulation options available—ranging from polyurethane foam to fiberglass—will allow users to make informed decisions tailored to their specific needs. Whether for shipping goods or creating innovative living spaces, the right shipping container insulation can enhance performance and promote sustainability.

Assessing Your Insulation Needs for Shipping Containers

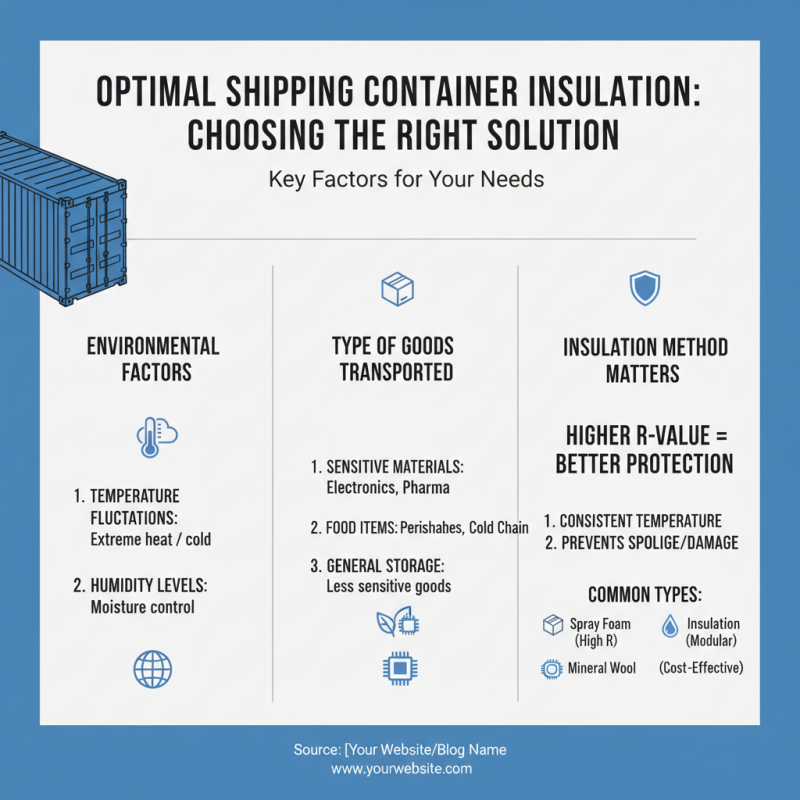

When assessing your insulation needs for shipping containers, it’s essential to consider the specific environment in which the container will operate. Factors such as temperature fluctuations, humidity levels, and the type of goods being transported all play a crucial role in determining the best insulation method. For instance, if you are storing sensitive materials or food items, a higher R-value insulation will help maintain a consistent internal temperature and protect against spoilage.

Tips: Evaluate your geographical location and the typical weather conditions you expect the container to encounter. This information will guide you to choose insulation materials that offer adequate protection against both heat and cold. Additionally, consider the ease of installation and the weight of the insulation material, as heavier options may affect the overall mobility of the container.

Another critical consideration is the insulation’s durability and moisture resistance. Shipping containers can be exposed to various conditions, including saltwater in coastal areas. Therefore, selecting insulation that can withstand humidity and resist mold growth is vital.

Tips: Research insulation materials like spray foam or rigid foam boards, which often provide excellent moisture resistance while ensuring structural integrity. Understanding your precise needs and doing thorough research will lead to better decisions on the materials that will keep your container’s cargo safe and secure.

Understanding Different Types of Shipping Container Insulation

When considering the best shipping container insulation for your needs, it's essential to understand the different types of insulation materials available on the market. The most common options include foam board insulation, spray foam insulation, and reflective insulation. According to a report from the International Journal of Refrigeration, foam board insulation boasts a thermal resistance (R-value) ranging from 3.5 to 8 per inch, making it a highly effective choice for maintaining temperature within the container. This type is particularly advantageous in environments where temperature extremes are prevalent, as it provides a sturdy barrier against external conditions.

Spray foam insulation, on the other hand, offers similar thermal resistance but provides the added benefit of air sealing, which can significantly reduce heat loss. Industry data from the Building Science Corporation indicates that closed-cell spray foam can achieve an R-value of 6 to 7 per inch, which is ideal for shipping containers used as mobile cold storage units or living spaces. Meanwhile, reflective insulation, which is often made from aluminum foil and works by reflecting radiant heat, can be an excellent choice for environments with high thermal radiation, improving energy efficiency in conjunction with other insulation types.

Understanding these options allows for informed decision-making when selecting insulation based on specific needs such as climate, intended use, and budget. Each type of insulation plays a crucial role in optimizing energy efficiency and extending the lifespan of the shipping container, making it vital to choose the right one for your unique application.

Evaluating Insulation Materials for Climate and Environment

When evaluating insulation materials for shipping containers, it's essential to consider the climate in which the container will be used. For hotter environments, reflective materials such as radiant barrier insulation can effectively reduce heat buildup by reflecting sunlight away from the container's interior. This type of insulation helps maintain lower temperatures, making it ideal for regions with extreme heat. Conversely, in colder climates, insulation materials that provide substantial thermal resistance, such as foam panels or fiberglass, can help retain warmth. These materials minimize heat loss, creating a more energy-efficient environment inside the container.

Another critical aspect to consider is the environmental impact of the insulation materials. Opting for eco-friendly options can significantly contribute to sustainability efforts, as many conventional insulation materials may release harmful chemicals or require extensive energy to produce. Materials made from recycled content or those that are biodegradable, like cellulose insulation, offer effective thermal performance while also being kind to the planet. Additionally, it's crucial to assess the moisture resistance properties of insulation materials to prevent mold and degradation, particularly in humid climates, ensuring that the integrity of the container and its contents is preserved over time.

Installation Techniques for Shipping Container Insulation

When installing insulation in a shipping container, there are several techniques to ensure optimal efficiency and comfort. One popular method is to use rigid foam board insulation, which can easily be adhered to the interior walls of the container. This technique is relatively straightforward: first, measure the dimensions of the walls and cut the foam boards accordingly. Use an adhesive designed for foam insulation to secure the boards to the container’s walls, ensuring there are no gaps that could compromise thermal performance. This method not only improves insulation but also adds minimal weight to the shipping container.

Another effective installation technique involves using spray foam insulation. This option is particularly advantageous for its ability to fill in all nooks and crannies without requiring precise measurements. To apply spray foam, it’s essential to prepare the container by cleaning the surfaces and ensuring they are dry. Following safety precautions, a spray foam kit can be used to cover the walls and ceiling thoroughly. As the foam expands and hardens, it creates an airtight seal that can significantly reduce heat loss or gain, making the shipping container more energy-efficient. Each of these techniques offers unique benefits, allowing you to choose the best solution for your insulation needs based on your project requirements.

Cost Considerations When Choosing Insulation Options

When considering insulation options for shipping containers, cost is a critical factor that can significantly influence your decision. Industry reports indicate that the average cost of insulation materials can vary widely, ranging from $0.50 to $3.00 per square foot, depending on the type of insulation selected. For instance, fiberglass batts are often on the lower end of the price spectrum, while spray foam insulation, known for its superior thermal resistance and air sealing properties, tends to be more expensive but may justify the higher upfront cost over time through energy savings.

Additionally, it's essential to factor in the long-term implications of your insulation choice. According to the U.S. Department of Energy, well-insulated buildings can save up to 20% on heating and cooling costs annually. Therefore, while initial installation costs are crucial, assessing the potential return on investment through energy efficiency can lead to better overall cost management. Moreover, considering the lifespan and maintenance requirements of different insulation options can help to avoid unexpected expenses down the line. Effective planning and understanding of these cost considerations will help in selecting the best insulation for your shipping container needs.

Related Posts

-

2025 Top 5 Shipping Cargo Containers for Efficient Global Logistics Solutions

-

Innovative Shipping Container Restaurant Concepts Transforming Urban Dining Experiences

-

Understanding Container Insulation: The Key to Energy Efficiency in Shipping and Storage

-

Discover the Best Uses for Free Shipping Containers in 2025

-

Top 5 Benefits of Using Large Shipping Containers for Your Business Logistics

-

Unlocking Value: The Sustainable Benefits of Using Second Hand Storage Containers for Your Home