2025 How to Insulate Shipping Containers for Maximum Energy Efficiency

As the popularity of shipping containers for various applications continues to rise, the importance of effective shipping container insulation cannot be overstated. According to a recent report by the International Energy Agency (IEA), improvements in insulation can reduce energy consumption by up to 30% in structures that rely on temperature control. This statistic highlights the significant role that insulation plays in enhancing the energy efficiency of these versatile living spaces and commercial units.

Industry expert Dr. Emily Harrington, a prominent figure in sustainable building practices, emphasizes this need for insulation by stating, “Proper shipping container insulation not only regulates temperature but also minimizes environmental impact by reducing energy demands.” Insulating shipping containers effectively not only makes them comfortable to live or work in but also significantly decreases heating and cooling costs, creating a more environmentally friendly footprint.

In conclusion, with the rising energy costs and the ongoing demand for sustainable living options, investing in quality shipping container insulation is more critical than ever. By leveraging innovative insulation methods and materials, container owners can achieve maximum energy efficiency, benefiting both their financial bottom line and the planet.

Understanding the Importance of Insulation in Shipping Containers

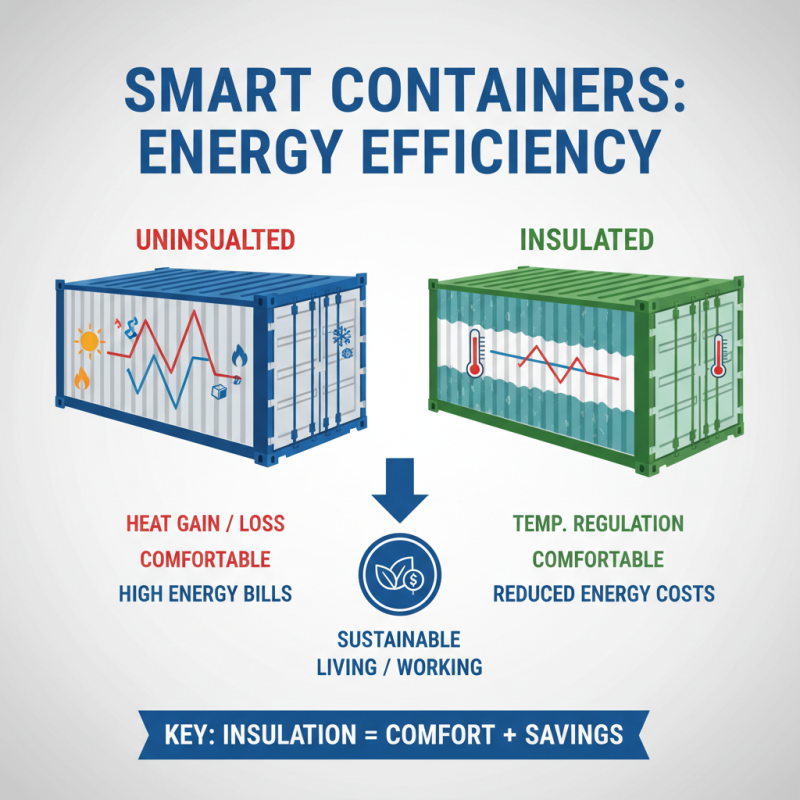

Insulation plays a crucial role in maximizing the energy efficiency of shipping containers, making them viable living or working spaces. Given the metal construction of these containers, they tend to absorb and radiate heat quickly. Without proper insulation, the internal climate can become unbearable, leading to excessive energy consumption for heating or cooling purposes. Understanding the impact of insulation is essential for anyone considering a shipping container project, as it not only enhances comfort but also significantly reduces energy costs.

When choosing the right insulation method, it's important to consider both thermal and acoustic properties. Various insulation materials, such as foam boards, spray foam, or reflective barriers, can be employed depending on the intended use of the container. Properly insulated containers can maintain a stable internal temperature, which is crucial for agricultural storage, residential living, or office environments. Moreover, good insulation helps minimize external noise, creating a more peaceful atmosphere. Investing in insulation not only prolongs the lifespan of the container but also contributes to sustainable energy practices by reducing the carbon footprint associated with excessive heating and cooling.

Evaluating Different Insulation Materials for Shipping Container Efficiency

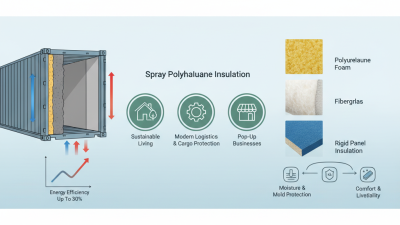

Insulating shipping containers effectively is crucial for maximizing energy efficiency, especially as more individuals and businesses turn to these versatile structures for various uses. Evaluating different insulation materials reveals significant differences in thermal performance and energy savings. For instance, according to the U.S. Department of Energy, high-quality insulation can reduce energy consumption by up to 30% in heated spaces.

When it comes to insulation materials, options such as spray foam, rigid foam boards, and fiberglass all offer distinct advantages. Spray foam, known for its superior air sealing capabilities, can provide an R-value of 6.5 to 7.0 per inch, which is highly beneficial for maintaining consistent indoor temperatures.

Rigid foam boards also present a practical solution, often achieving R-values ranging from 3.8 to 6.5 per inch, depending on the type. This makes them ideal for container insulation, as they are relatively lightweight and easy to install while also offering moisture resistance. On the other hand, fiberglass insulation, although generally less effective in terms of R-value per inch—around 2.9 to 4.3—can be a cost-effective option for larger projects. Recent studies indicate that choosing the right insulation can significantly contribute to the container's energy efficiency, offering not just immediate comfort but also long-term savings in energy costs. Therefore, an informed selection of insulation materials is key to enhancing the sustainability of shipping containers.

Step-by-Step Guide to Insulating Shipping Containers Effectively

When insulating shipping containers for maximum energy efficiency, it's crucial to follow a systematic approach. Start by selecting the appropriate insulation material, such as spray foam, rigid foam boards, or fiberglass. According to the U.S. Department of Energy, insulation with a higher R-value—indicating better thermal resistance—can significantly impact energy consumption. For instance, the recommendation for residential structures is to use insulation with at least an R-value of 30. Given that a standard shipping container's thermal performance can be poor due to its metal structure, opting for high R-value materials can enhance comfort and energy efficiency.

Next, ensure that you check for any gaps or openings that may compromise your insulation efforts. A study by the National Renewable Energy Laboratory highlights that irregularities in insulation, often resulting from improper sealing, can lead to thermal bridges that allow heat loss in winter and heat gain in summer. Sealing gaps not only improves the overall insulation but also contributes to reducing energy costs by nearly 20-30%. Once the container is properly sealed, apply the insulation material effectively, keeping in mind that layering can provide additional benefits. Emphasizing each step in this process will lead to a more comfortable and energy-efficient shipping container environment, suitable for various applications.

Energy Efficiency of Insulated Shipping Containers

Maximizing Energy Efficiency: Best Practices for Shipping Container Usage

Maximizing energy efficiency in shipping containers is essential for sustainable living and effective resource management. To achieve this, it is crucial to focus on proper insulation methods that not only reduce energy consumption but also enhance indoor comfort. According to the U.S. Department of Energy, uninsulated containers can lead to excessive energy loss, with heat gains of up to 10 times greater compared to well-insulated structures. Consequently, investing in quality insulation materials can significantly decrease heating and cooling costs, making the space more viable for long-term use.

One of the best practices for enhancing energy efficiency in shipping containers is the use of spray foam insulation, which has a high R-value per inch and provides an effective air barrier. The Oak Ridge National Laboratory reports that well-insulated buildings can cut energy costs by up to 40%. For shipping containers, achieving an R-value between 25 to 30 is ideal, allowing for optimal thermal performance. Additionally, incorporating reflective roofing materials can further mitigate heat absorption, particularly in warmer climates, thereby reducing the reliance on air conditioning systems. Overall, these strategies contribute to a more sustainable approach to utilizing shipping containers, promoting energy efficiency and reducing carbon footprints.

Cost-Benefit Analysis of Insulating Shipping Containers in 2025

Insulating shipping containers has become increasingly important in enhancing energy efficiency, especially as the demand for sustainable living spaces grows. According to a 2023 report from the International Energy Agency, poorly insulated structures can lose up to 30% of heating or cooling energy, significantly impacting energy bills over time. This makes the cost of insulation not just a mere addition to the budget but a critical investment. A recent cost-benefit analysis indicates that insulating shipping containers in 2025 may cost between $1,500 and $5,000, depending on the materials used. However, given the potential savings on energy bills, which can reach 20-40% annually, the return on investment can be realized in merely three to five years.

Moreover, a study published by the Global Insulation Association highlights that insulated structures improve indoor comfort, which can be crucial for residential and commercial enterprises utilizing shipping containers as living or workspaces. Enhanced insulation not only reduces temperature fluctuations but also minimizes the need for constant climate control, thus leading to further energy savings. With energy costs projected to rise by up to 10% annually in the coming years, the financial advantage of insulating shipping containers becomes even more pronounced as homeowners and businesses seek to mitigate future utility expenses and embrace energy-efficient practices.

Related Posts

-

How to Choose the Best Shipping Container Insulation for Your Needs

-

Exploring the Future of Sustainable Living with Container Cabins

-

Maximize Your Space: The Rising Trend of Second Hand Storage Containers in Urban Living

-

Discover the Best Uses for Free Shipping Containers in 2025

-

Unlocking the Future of Sustainable Living through Innovative Container Conversions

-

Understanding Container Insulation: The Key to Energy Efficiency in Shipping and Storage