10 Tips for Efficiently Using Freight Containers in Your Shipping Operations

In today’s globalized economy, the efficient use of freight containers is paramount to enhancing shipping operations and minimizing costs. According to a report by the World Shipping Council, over 90% of the world's trade is carried by sea, with freight containers serving as the backbone of this logistics network. The optimization of container utilization not only streamlines the supply chain but also contributes significantly to sustainability efforts by reducing carbon footprints associated with transport.

Expert in logistics optimization, Dr. Emily Carter, highlights the importance of embracing innovative practices in freight container management: "Efficient use of freight containers can transform shipping operations and lead to significant cost savings,” she states. As businesses strive to maintain competitive edges, mastering the art of container usage becomes increasingly crucial. This guide outlines ten actionable tips that can significantly improve freight container management, ensuring that companies harness their full potential while navigating the challenges of the shipping industry.

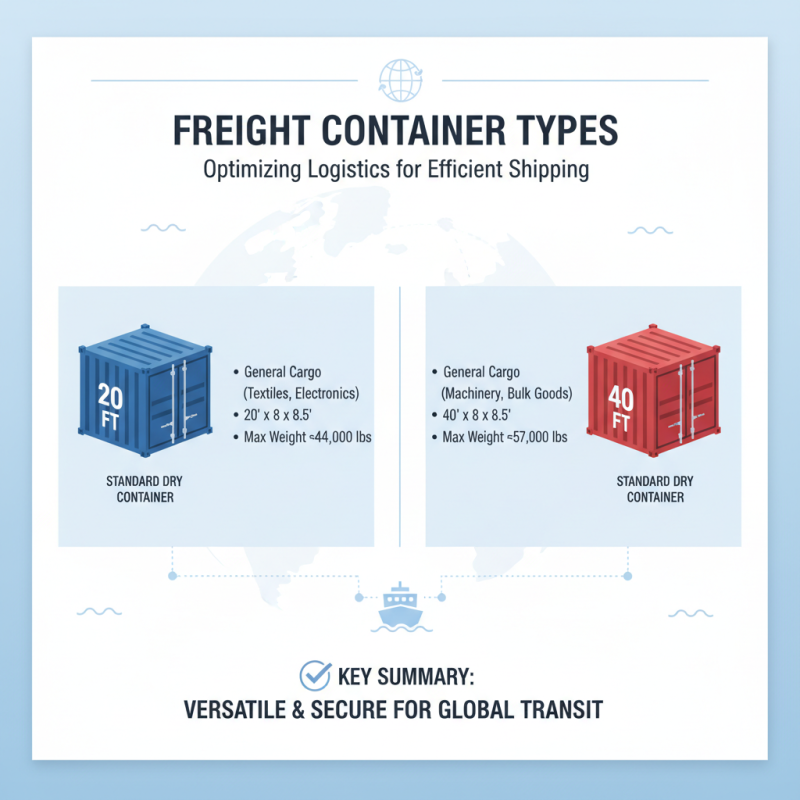

Understanding Freight Container Types and Their Specifications

When it comes to efficient shipping operations, understanding freight container types and their specifications is essential for optimizing logistics. Freight containers are available in various styles, each designed to cater to specific types of cargo. The most common type is the standard 20-foot and 40-foot dry container, which is versatile and suitable for shipping general cargo such as textiles, electronics, and machinery. These containers are built to withstand the rigors of transit, providing a secure environment for goods while minimizing exposure to external elements.

In addition to standard containers, there are specialized types such as refrigerated containers (reefer containers) used to transport perishable items that require temperature control. These containers come equipped with advanced refrigeration systems that maintain a consistent climate, thus preserving the quality of goods such as food products and pharmaceuticals. Another type is the open-top container, which allows for loading and unloading of oversized cargo from the top, accommodating items that cannot fit through standard doors. Additionally, flat rack containers offer flexibility for heavy machinery and large cargo, as they can be easily loaded from the sides or above. By selecting the appropriate container type, businesses can significantly enhance their shipping efficiency, reduce costs, and improve overall supply chain management.

Optimizing Container Loading Techniques for Maximum Space Utilization

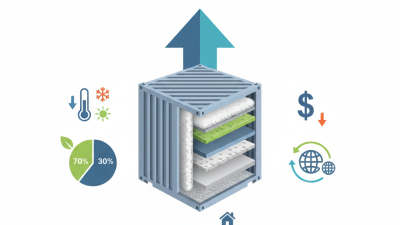

Efficient loading techniques for freight containers can significantly enhance shipping operations, leading to improved profitability and reduced costs. Industry reports estimate that optimizing container loading can increase available space utilization by up to 30% (Source: Freight Transport Association). This is crucial as shipping costs are typically calculated based on weight and volume; maximizing container capacity can allow businesses to transport more goods while minimizing the number of shipments required.

One effective method is to strategically arrange cargo based on weight and shape, ensuring that heavier items are placed at the bottom and lighter ones on top. This not only maximizes vertical space but also stabilizes the load, minimizing the risk of damage during transit. Furthermore, utilizing standardized pallets and modular packaging can streamline loading processes. According to a study by the World Shipping Council, companies that implement such optimized loading techniques report a 25% decrease in loading time, further enhancing operational efficiency.

Additionally, technological advancements have made it easier to visualize and plan container loading. Software applications that simulate loading scenarios can assist in determining the most space-efficient arrangement of goods. Research indicates that employing these advanced loading software solutions can improve loading efficiency by up to 20% compared to traditional methods, highlighting the importance of integrating modern technology in shipping operations. By adopting these practices, businesses can achieve greater logistical efficiency and maintain a competitive edge in the shipping industry.

Implementing Technology for Streamlined Inventory Management

Implementing technology into inventory management is crucial for optimizing the use of freight containers in shipping operations. Advanced inventory management systems can facilitate real-time tracking of goods within containers, ensuring efficient stock management and reducing the risk of overstocking or stockouts. By using barcode scanning and RFID technology, businesses can gain accurate insights into their inventory levels and movement, allowing for better decision-making regarding shipping schedules and container utilization.

Moreover, leveraging cloud-based solutions can enhance collaboration among teams, enabling seamless access to inventory data from multiple locations. This integration not only improves visibility across the supply chain but also enhances communication between warehouses and shipping departments. Automated notifications can alert staff about low inventory levels or delays in shipping, allowing for proactive measures and efficient reordering processes. Ultimately, adopting these technological advancements will streamline operations, reduce costs, and ensure that freight containers are used to their fullest potential, enhancing overall shipping efficiency.

Freight Container Usage Analysis

This bar chart illustrates the efficiency of freight container usage across different shipping operations based on technology implementation for inventory management. The data reflects the percentage of operations utilizing various technologies to streamline their processes.

Adhering to Regulatory Compliance and Safety Standards in Shipping

When it comes to shipping operations, adhering to regulatory compliance and safety standards is paramount. Ensuring that freight containers meet the necessary legal and safety requirements not only safeguards the cargo but also protects everyone involved in the shipping process. Familiarize yourself with local and international shipping laws to avoid hefty fines and possible delays in the transportation of goods.

To enhance compliance, consider conducting regular audits of your shipping practices. This includes reviewing documentation to ensure that all freight containers are properly labeled and in good condition. Moreover, investing in training for your staff on safety protocols can minimize the risks associated with handling and transporting containers.

When using freight containers, efficiency can be elevated by consolidating cargo to maximize space while still adhering to weight restrictions. Proper load planning not only promotes safety on the road but also ensures compliance with shipping regulations. Additionally, maintaining open lines of communication with regulatory bodies and industry stakeholders can help you stay updated on any changes in compliance standards that may impact your shipping operations.

10 Tips for Efficiently Using Freight Containers in Your Shipping Operations

| Tip | Description | Compliance Aspect | Safety Standard |

|---|---|---|---|

| 1. Select the Right Container | Choose containers that fit the type of cargo and its handling requirements. | ISO Standard Container Types | CSC Safety Regulations |

| 2. Maintain Regular Inspections | Conduct routine checks for structural integrity and cleanliness. | Regulatory Compliance Audits | Safety Maintenance Standards |

| 3. Proper Loading Techniques | Distribute weight evenly and secure loads to prevent shifting. | Load Planning Standards | Occupational Safety Guidelines |

| 4. Use Tracking Technology | Implement GPS tracking to monitor container locations. | Data Protection Regulations | Cargo Security Standards |

| 5. Ensure Ventilation | Prevent moisture buildup by ventilating containers appropriately. | Health and Safety Regulations | Hazardous Material Standards |

| 6. Train Staff Properly | Provide training for safe handling and emergency procedures. | Personnel Safety Compliance | Workplace Safety Standards |

| 7. Utilize Secure Fastening Methods | Use strapping and other methods to keep cargo secure. | Lashing and Securing Guidelines | Safety Fastening Standards |

| 8. Monitor Container Conditions | Evaluate container conditions during transit. | Environmental Compliance | Cargo Damage Prevention Standards |

| 9. Review Regulatory Changes | Stay updated with changes in shipping regulations. | Regulatory Compliance Updates | Safety Policy Revisions |

| 10. Keep Emergency Contacts Handy | Have emergency contacts for quick response. | Emergency Preparedness Regulations | Safety Procedure Compliance |

Analyzing Cost-Effectiveness of Container Shipping vs. Other Methods

When considering shipping operations, cost-effectiveness is a pivotal factor that can influence business decisions. Container shipping stands out due to its ability to transport large quantities of goods at a relatively low per-unit cost. This efficiency primarily stems from the economies of scale achieved when utilizing freight containers. By transporting multiple units in a single container, businesses can minimize shipping expenses while maximizing delivery efficiency, making it a preferred choice over other shipping methods, such as air freight, which often incurs significantly higher costs for smaller shipments.

However, it is important to analyze the broader context of shipping methods. While container shipping is generally more cost-effective for bulk shipments, other options may be more advantageous depending on specific operational needs. For example, if time is a critical factor, air freight might be justified despite its higher costs. Additionally, regional considerations and logistical capabilities can also impact shipping strategy, as some areas may be more accessible for container transport, while others may favor road or rail options. Ultimately, a thorough evaluation of these factors will not only highlight the potential savings from using freight containers but also ensure that shipping operations remain agile and responsive to market demands.

Related Posts

-

2025 Top 5 Transport Containers: Industry Insights & Market Trends for Growth

-

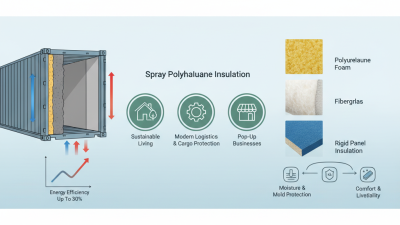

How to Choose the Best Shipping Container Insulation for Your Needs

-

How to Choose the Best Large Shipping Container for Your Needs

-

Exploring the Future of Sustainable Living with Container Cabins

-

2025 How to Insulate Shipping Containers for Maximum Energy Efficiency

-

Discover the Best Uses for Free Shipping Containers in 2025